Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

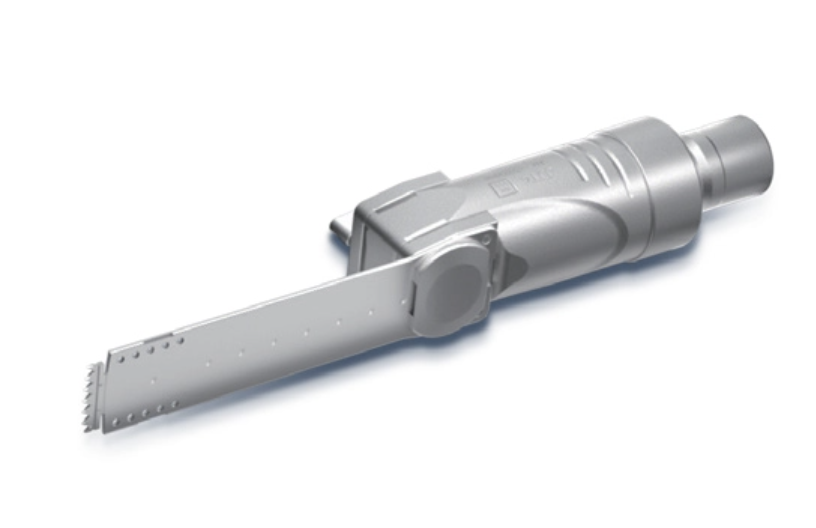

Sagittal saw blades and handpieces are vital in orthopedic surgery, but even reliable tools can face cutting issues or vibration over time. That is why troubleshooting sagittal saw blade problems matters. In this guide, we share practical fixes and maintenance tips, and with trusted solutions like Xishan products, you can keep performance stable and safe, and learn more about our products.

The first step in solving problems is noticing small changes before they become major failures. Surgeons and technicians often report subtle warning signs, such as unusual noise, reduced cutting speed, or slight wobbling of the sagittal saw blade. These early symptoms may seem minor, but they often indicate mechanical wear or improper attachment. If ignored, performance can decline quickly, especially in high-use surgical environments. Recognizing these signals helps teams act faster, reduce downtime, and prevent unexpected tool failure during procedures. Early troubleshooting protects both equipment investment and patient safety, which is why consistent monitoring is essential, particularly when using high-frequency oscillating saw attachments engineered for low vibration.

Sagittal saw blades are designed for clean, controlled bone cuts. When performance drops, precision suffers. A dull blade may require extra pressure, which can lead to uneven cuts or excessive heat generation. In orthopedic surgery, even small inaccuracies can affect implant fit or healing outcomes. Poor cutting performance also increases procedure time, which may impact operating room efficiency. Troubleshooting sagittal saw blade problems is not only about tool care, it is about ensuring surgical accuracy. By understanding how blade wear, alignment issues, and handpiece power loss connect, teams can maintain consistent surgical results, especially in modern minimally invasive surgery workflows supported by powered surgical instrument platforms.

Delaying troubleshooting often leads to larger repair costs and greater disruption. A small vibration issue, for example, can accelerate blade wear and damage internal handpiece components. Over time, this creates a cycle of repeated failures. Fast diagnosis helps reduce replacement frequency and ensures tools remain reliable. In busy hospitals, equipment downtime can delay cases and increase logistical pressure. Addressing issues quickly improves operational stability and reduces long-term maintenance costs. It also supports compliance with clinical standards, since well-maintained orthopedic power tools are safer and more dependable in sterile environments, which is a key focus for globally adopted manufacturers such as Xishan in the powered surgical instruments sector.

Not every cutting problem comes from the blade itself. Sometimes the sagittal saw handpiece is the real source of failure. A weak motor, worn gears, or overheating components can reduce blade performance even if the blade is new. On the other hand, a damaged blade can cause vibration that stresses the handpiece. Effective troubleshooting requires separating these factors. Teams should test blades across multiple handpieces when possible, and inspect attachment systems carefully. Understanding whether the issue is mechanical, electrical, or related to consumable wear ensures the right fix is applied without unnecessary part replacement.

Tip: Always document recurring problems, since patterns often reveal whether blades or handpieces are the root cause.

Issue Observed | Likely Cause | Recommended Action |

Blade not cutting properly | Dull blade | Replace blade promptly |

Excessive vibration | Misalignment or loose locking | Check installation and locking |

Handpiece overheating | Motor strain or poor lubrication | Service handpiece and reduce load |

One of the most common complaints is a sagittal saw blade not cutting properly. In most cases, dullness is the primary cause. Blades wear down after repeated use, sterilization cycles, and contact with dense bone. As sharpness decreases, cutting becomes slower and requires more force. This increases heat, reduces precision, and may strain the handpiece motor. Worn-out blades should be replaced promptly rather than pushed beyond their service life. Regular inspection for chipped edges or surface fatigue helps prevent poor performance. In high-demand orthopedic settings, blade replacement schedules are essential for consistent outcomes, regardless of whether teams use standard blades or specialized low-vibration attachment series.

Blade alignment issues are another frequent source of cutting problems. If the blade is not seated correctly, it may wobble or cut unevenly. Misalignment can occur due to improper installation, wear in the locking mechanism, or compatibility issues between blade and handpiece models. Even slight misalignment reduces efficiency and increases vibration. Proper alignment ensures smooth oscillation and clean cuts. Technicians should verify that blades lock firmly and remain stable under load. Troubleshooting sagittal saw blade vibration often begins with checking alignment, since stability is directly tied to cutting accuracy and tool longevity, which is why quick-lock interface designs are increasingly valued.

Not all sagittal saw blades are designed for the same tasks. Using the wrong blade type can cause cutting inefficiency and faster wear. Some blades are optimized for fine precision, while others are designed for aggressive cutting in dense bone. Selecting an unsuitable blade increases procedure time and may lead to overheating. Surgical teams should match blade design to the clinical application. Standardizing blade selection protocols reduces confusion and ensures tools perform as expected. Correct blade choice is a simple but powerful way to avoid common sagittal saw blade problems in the operating room.

Vibration is both a symptom and a cause of performance decline. If a blade vibrates excessively, it may indicate looseness, imbalance, or wear. Vibration reduces control and may damage surrounding tissues if precision is lost. It also accelerates mechanical fatigue in the handpiece. Troubleshooting sagittal saw blade vibration involves inspecting attachment points, checking blade integrity, and ensuring motor output is stable. If vibration persists across multiple blades, the handpiece may require repair. Addressing vibration early protects both the equipment and surgical performance, which is why manufacturers like Xishan emphasize precision transmission structures for stable power delivery.

A loose locking mechanism is one of the most common mechanical causes of instability. When the blade does not lock securely, it shifts during operation. This creates vibration, uneven cuts, and increased wear. Over time, repeated attachment cycles can degrade locking components. Surgical teams should inspect locking systems regularly for wear or contamination. A simple cleaning and lubrication step may restore proper locking performance. However, if mechanical wear is advanced, replacement parts may be needed. Stability is critical in orthopedic power tools, so locking integrity must never be overlooked, especially in high-frequency oscillating saw attachment systems.

Sometimes vibration originates inside the handpiece rather than the blade. Internal imbalance, worn bearings, or damaged gears can disrupt smooth oscillation. Even if the blade is new, the handpiece may produce unstable motion. This reduces surgical precision and increases fatigue for the user. Troubleshooting should include testing the handpiece under load and listening for unusual motor sounds. Handpiece imbalance often requires professional surgical saw repair, since internal components are complex. Identifying imbalance early prevents further damage and helps extend tool lifespan.

Vibration creates stress that accelerates blade fatigue. When a blade oscillates unevenly, micro-cracks can form along the cutting edge. This leads to faster dulling and potential breakage. Vibration also increases friction, generating more heat and reducing cutting efficiency. Over time, the blade may require replacement much sooner than expected. This increases consumable costs and disrupts workflow. Understanding the relationship between vibration and wear helps teams prioritize stability checks as part of routine sagittal saw handpiece maintenance guide practices.

Preventing instability requires a combination of correct blade installation, regular maintenance, and careful handling. Tools should be stored properly to avoid accidental drops that may bend components. Sterilization protocols should be followed carefully, since corrosion can affect locking systems. Routine inspections before each procedure help detect early issues. Stability is essential for safe surgical performance, so prevention is always more cost-effective than repeated repairs, particularly for sealed high-temperature materials designed to withstand repeated autoclave cycles.

Handpiece overheating is a serious issue that can interrupt surgery and shorten tool lifespan. Overheating often occurs when motors are under strain, lubrication is insufficient, or ventilation pathways are blocked. Excessive cutting pressure also increases heat generation. When a sagittal saw handpiece overheats, performance drops quickly and safety risks rise. Teams should monitor temperature changes during extended procedures. Overheating is often a warning sign that maintenance schedules need improvement. Understanding root causes allows faster troubleshooting and helps prevent repeated failures, which is why low-temperature-rise engineering is a key differentiator in premium attachment designs.

Power loss is closely linked to overheating. When the motor is strained, torque output declines, and the blade may stall or cut inconsistently. This forces the surgeon to apply more pressure, creating a feedback loop of increased heat and reduced efficiency. Reduced torque may also indicate electrical wear or internal mechanical resistance. Troubleshooting should include checking battery systems, motor condition, and load performance. Maintaining strong torque output ensures smooth cutting and reduces stress on both blade and handpiece components.

If overheating occurs frequently, professional surgical saw repair may be required. Internal motor wear, damaged bearings, or electrical faults often cannot be fixed through routine cleaning. Repair specialists can assess whether components need replacement or recalibration. Hospitals should establish clear thresholds for when handpieces are removed from service. Continuing to use overheating tools can cause sudden failure and higher repair costs. Proper repair planning ensures tools remain safe and compliant with clinical standards.

Preventing overheating involves reducing strain and improving maintenance. Teams should replace dull blades promptly, since sharp blades cut efficiently and generate less heat. Lubrication schedules must be followed carefully. Operators should avoid excessive pressure, letting the tool perform the work. Proper cooling periods between cases also help. Overheating prevention is part of a broader sagittal saw handpiece maintenance guide approach, ensuring consistent performance and reducing unexpected downtime, especially in multi-functional powered surgical instrument platforms.

Sagittal saw handpiece malfunction can occur due to mechanical wear, electrical faults, or contamination. Fixing these issues begins with diagnosis. Teams should check whether the handpiece powers on consistently, whether oscillation remains stable, and whether attachment systems function properly. Simple fixes may include cleaning connectors or replacing consumable parts. However, deeper mechanical failures often require professional intervention. Understanding common malfunction patterns helps hospitals respond quickly and avoid repeated disruptions in surgical workflows.

Handpieces rely on gears and bearings to transfer motor power into oscillating blade motion. Over time, these components wear down, leading to noise, vibration, and reduced cutting performance. Internal wear often develops gradually, making early detection difficult. Routine performance testing helps identify declining efficiency before failure occurs. When gears and bearings degrade, surgical saw repair becomes necessary. Replacing internal parts restores tool function and prevents sudden breakdowns during critical procedures.

Control mechanisms such as triggers and speed settings also fail with repeated use. A trigger that sticks or responds inconsistently can disrupt surgical flow. These failures may be caused by mechanical fatigue or contamination from sterilization residue. Troubleshooting includes inspecting control surfaces, ensuring smooth movement, and verifying electrical responsiveness. Trigger issues may seem minor, but they directly affect surgeon control. Prompt repair improves safety and usability in demanding clinical environments.

Not all problems can be solved in-house. Persistent vibration, overheating, or mechanical instability often require professional repair services. Hospitals should work with certified providers who understand orthopedic power tools. Repair decisions should consider cost, downtime, and safety compliance. Attempting unauthorized repairs may void warranties or introduce new risks. Knowing when to escalate issues ensures tools remain reliable and safe for surgical teams.

Blade replacement decisions depend on wear level, procedure demands, and manufacturer guidance. Some blades are disposable, while others may support limited resharpening. However, resharpening can reduce structural integrity if done improperly. Replacing blades at the right time ensures consistent cutting performance and reduces overheating risk. Hospitals should track blade usage cycles to prevent overuse. Proper replacement practices reduce troubleshooting frequency and improve surgical efficiency.

Correct installation is essential for avoiding blade alignment issues. A blade must seat firmly and lock securely before operation. Even small installation errors can cause vibration and uneven cuts. Teams should follow standardized attachment protocols and verify stability through manual testing. Proper installation reduces wear on locking systems and improves overall tool reliability. Consistency in installation practices is one of the simplest ways to prevent recurring sagittal saw blade problems.

Compatibility is often overlooked. Not all sagittal saw blades fit every handpiece model, even if they appear similar. Using incompatible components can lead to poor locking, vibration, and premature wear. Hospitals should maintain clear inventories of approved blade-handpiece pairings. Staff training is essential to prevent accidental mismatches. Compatibility control reduces troubleshooting workload and ensures tools perform as designed, particularly for systems where attachments are engineered to integrate seamlessly with a specific powered host platform.

Safe replacement procedures protect both staff and patients. Blades should be handled carefully to avoid injury, and sterile technique must be maintained. Replacement should occur in controlled environments with proper inspection steps. Teams should confirm locking integrity before use. Safe procedures reduce the risk of blade detachment during surgery and support compliance with operating room standards.

Cleaning is the foundation of maintenance. Blood, tissue residue, and sterilization chemicals can build up in handpiece components. Proper cleaning protocols prevent corrosion and contamination that may affect performance. Teams should follow manufacturer instructions closely and avoid harsh methods that damage seals. Effective cleaning reduces infection risk and improves mechanical reliability. Consistent cleaning routines are essential for long-term performance of sagittal saw handpieces, especially those built with fully sealed, high-temperature-resistant materials.

Lubrication reduces friction in moving components and prevents overheating. Inspection routines help identify early wear in locking systems, gears, and bearings. Hospitals should schedule lubrication based on usage frequency. Inspections should include checking for vibration, noise, and attachment stability. These steps extend tool lifespan and reduce repair costs. A proactive sagittal saw handpiece maintenance guide approach supports consistent surgical performance.

Corrosion is a hidden threat in surgical tools. Moisture exposure during sterilization can lead to rust in internal components. Contamination buildup also reduces locking performance and motor efficiency. Preventing corrosion requires proper drying, storage, and adherence to sterilization protocols. Teams should monitor tools for discoloration or residue. Preventing buildup protects both safety and equipment investment.

Scheduled maintenance ensures tools remain reliable across high-use environments. Hospitals should track service intervals, usage cycles, and repair history. Preventive maintenance reduces emergency breakdowns and supports predictable performance. Investing in maintenance is more cost-effective than frequent replacements. Long-term reliability depends on disciplined care practices.

Blades wear faster when operators apply excessive force. Sagittal saws are designed to cut efficiently without heavy pressure. Overloading the blade increases friction, heat, and edge damage. Training surgeons and staff on correct technique reduces wear and improves safety. Proper technique extends blade life and reduces troubleshooting frequency.

Sterilization cycles expose blades to heat, moisture, and chemicals. Over time, these factors weaken metal integrity and accelerate dulling. Hospitals should monitor sterilization protocols carefully and replace blades according to guidelines. Understanding sterilization impact helps teams plan consumable budgets and reduce unexpected failures.

High-use environments create constant stress on blades. Micro-fatigue accumulates with each procedure, eventually reducing cutting performance. Material fatigue is unavoidable, but proper replacement schedules help manage it. Tracking blade usage prevents overextension beyond safe limits.

Improper storage can damage blades through bending, corrosion, or contamination. Blades should be stored in protective cases and kept dry. Organized storage reduces accidental damage and ensures readiness for procedures. Storage is a simple but often overlooked factor in blade longevity.

A blade that does not secure properly creates immediate safety risks. Loose attachment can cause vibration, uneven cuts, or detachment during surgery. Troubleshooting begins with inspecting locking mechanisms for wear or debris. Proper cleaning often resolves minor issues, but worn parts require replacement.

Locking mechanisms degrade over time due to repeated use. Wear reduces grip strength and increases instability. Repair solutions may include replacing locking components or servicing the handpiece. Preventive inspection helps identify wear early and reduces emergency failures.

Accidental detachment is rare but serious. Preventing it requires proper installation, routine testing, and maintenance. Teams should verify locking integrity before each case. Detachment prevention protects patient safety and maintains trust in surgical equipment.

Testing stability is a best practice. Manual checks confirm that blades are locked and aligned. Simple pre-procedure inspections reduce the chance of unexpected failure. Stability testing supports safer and more efficient surgical workflows.

Choosing blades designed for specific orthopedic tasks improves performance and reduces wear. Specialized blades cut more efficiently and generate less heat. Proper selection reduces troubleshooting frequency and enhances surgical precision.

Handpiece power must align with blade requirements. High-density cutting tasks require sufficient torque. Matching components ensures smooth operation and prevents motor strain. Compatibility improves reliability and reduces overheating risk.

Hospitals should evaluate tools based on durability, service support, and performance history. Investing in reliable systems reduces downtime and repair costs. Performance evaluation supports better long-term procurement decisions, and companies like Chongqing Xishan Science & Technology are often referenced in the industry for combining equipment engineering with clinical training infrastructure.

Quality equipment reduces recurring failures. While higher upfront costs may exist, long-term savings come from fewer repairs and replacements. Reliable sagittal saw blades and handpieces support smoother surgical operations.

Note: Procurement teams should consider lifecycle cost, not only purchase price, when selecting orthopedic power tools.

Troubleshooting sagittal saw blade problems needs skill and routine care. Dull blades, vibration, overheating, and locking faults can reduce precision and raise costs. By using structured fixes and a clear maintenance guide, teams improve safety and uptime. With reliable solutions like Xishan products, low vibration and quick-lock features help deliver stable cutting performance and long-term value.

Tip: Build a routine inspection checklist so troubleshooting becomes preventive rather than reactive.

A: Troubleshooting sagittal saw blade problems often involves dull blades, vibration, or poor cutting performance.

A: Follow a sagittal saw handpiece maintenance guide, check locking systems, and prevent overheating.

A: Reasons sagittal saw blades wear out quickly include high pressure, sterilization stress, and blade alignment issues.

+86-23-65764808

+86-23-65764808