Views: 0 Author: Site Editor Publish Time: 2026-02-06 Origin: Site

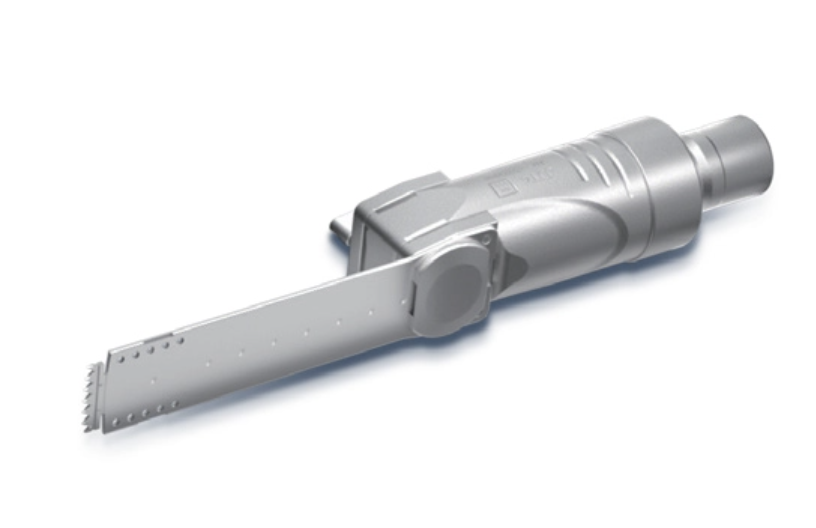

A sagittal saw is essential in modern surgery, and proper sagittal saw sterilization protects both patients and staff while keeping orthopedic power tools reliable over time. In this guide, you will learn how to sterilize a sagittal saw step by step, along with key surgical saw maintenance and blade care practices. High-quality systems from Xishan support repeated autoclave sterilization cycles, so you can learn more about our products and safe performance standards.

Cross-contamination is one of the most serious risks in surgery, and reusable tools like sagittal saws must be handled carefully. Even microscopic tissue residue can carry bacteria or viruses if sterilization is incomplete. This is why hospitals rely on strict medical instrument cleaning protocols. A sagittal saw has joints, crevices, and blade attachments that may trap debris. If these areas are missed, pathogens can survive and transfer between patients. Proper sterilization breaks this chain. It also supports compliance with infection prevention guidelines. When we understand the contamination risk, we see why step-by-step sagittal saw sterilization instructions are essential for every surgical department.

Operating room safety depends on reliable sterilization systems and disciplined staff routines. Surgical teams must trust that every orthopedic power tool entering the sterile field has been processed correctly. Sterilization is not only about killing bacteria but also about meeting regulatory expectations and accreditation audits. Hospitals often track sterilization cycles to confirm compliance. A sagittal saw that is not sterilized properly can compromise the sterile field and delay procedures. By following consistent surgical sagittal saw sterilization instructions, teams improve safety, reduce disruptions, and protect both patients and staff from preventable exposure.

Sterilization and maintenance are directly linked to equipment longevity. If cleaning is rushed, residue may harden and damage internal components over time. Moisture left inside can cause corrosion, which reduces performance. Instrument failure during surgery is costly and dangerous, requiring backup tools or delays. Preventive care reduces wear and ensures consistent cutting strength. Hospitals that invest in proper sagittal saw cleaning and maintenance guide practices often experience fewer repairs and lower replacement costs. This is why sterilization is not only a hygiene issue but also a long-term performance strategy.

The sterilization process begins right after the procedure ends. Immediate pre-cleaning prevents blood and tissue from drying onto the instrument. Once debris dries, it becomes harder to remove and may shield microbes from sterilization. Staff should wipe visible contamination using approved wipes or damp cloths. This early step reduces the bioburden before the saw reaches sterile processing. It also protects technicians who handle the device later. Quick action improves the effectiveness of the full sagittal saw sterilization process and reduces the risk of residue becoming trapped in moving parts.

Disassembly is critical because a sagittal saw includes removable blades and attachments. Sterilizing the tool while fully assembled can prevent steam or cleaning solutions from reaching hidden surfaces. Staff should follow manufacturer instructions for safe breakdown. Removing blades also protects workers from injury. Each component should be separated and placed in appropriate trays. This ensures thorough exposure during cleaning and autoclave sterilization. Disassembly also helps technicians inspect parts for wear. High-quality surgical power tool attachments, including quick-lock saw connections found in systems like Xishan’s orthopedic solutions, are designed to simplify safe disassembly and reassembly. When done correctly, it supports both infection control and preventive maintenance goals.

Not all detergents are safe for surgical saw maintenance. Harsh chemicals may damage seals, coatings, or internal mechanisms. Hospitals typically use neutral pH enzymatic cleaners designed for medical instrument cleaning. These solutions break down proteins and organic residue effectively. Choosing the right agent improves cleaning outcomes and reduces corrosion risk. Staff should avoid household cleaners or unapproved disinfectants. Using validated cleaning agents supports compliance and ensures the sagittal saw remains functional. Proper chemical selection is one of the simplest ways to protect both patients and equipment.

Cleaning methods vary depending on facility resources. Manual cleaning involves brushing, rinsing, and careful attention to joints and grooves. Ultrasonic cleaning uses sound waves to remove debris from hard-to-reach areas. Many hospitals combine both approaches for best results. Manual cleaning removes visible contamination, while ultrasonic systems address microscopic residue. The choice depends on instrument complexity and workload. A sagittal saw benefits from ultrasonic cleaning because debris can hide near blade mounts. Using the right method improves the overall sagittal saw cleaning and maintenance guide effectiveness.

Sagittal saws include internal channels and mechanical joints where debris can collect. Technicians must use small brushes and irrigation tools to reach these areas. If residue remains, it may compromise sterilization and lead to corrosion. Proper rinsing is also essential, as detergent buildup can interfere with autoclave cycles. Facilities should train staff to focus on these high-risk zones. Consistent cleaning reduces contamination risk and improves reliability. Thorough debris removal is one of the most important steps in surgical saw maintenance.

Best practices include standardized workflows, checklists, and staff accountability. Hospitals often create written surgical sagittal saw sterilization instructions to reduce variation. These instructions may include cleaning time limits, approved detergents, and inspection steps. Consistency matters because rushed processing increases error risk. Documentation also supports audits and quality control. When teams follow best practices, they reduce infection risk and extend tool lifespan. Standardization is key for safe orthopedic power tool processing.

Preparation includes drying, packaging, and correct tray placement. Excess moisture can lead to corrosion and incomplete sterilization. Components should be arranged so steam reaches all surfaces. Packaging materials must be compatible with autoclave cycles. Staff should also confirm that blades are removed or properly secured. Preparation ensures the autoclave sterilization process works effectively. Without proper setup, even the best equipment cannot sterilize correctly. Modern sealed, heat-resistant materials—such as those used in Xishan surgical saw attachments—are specifically engineered to withstand repeated 134°C sterilization demands. This step is essential for operating room safety.

Autoclave sterilization relies on validated time, temperature, and pressure settings. Common cycles may run at 121°C or 134°C depending on facility protocols. Staff must follow manufacturer recommendations to avoid damaging the sagittal saw. Incorrect settings can reduce sterilization effectiveness or shorten equipment life. Hospitals should regularly test autoclaves for performance. Maintaining proper cycle parameters ensures reliable sterilization outcomes and supports compliance with safety standards.

Mistakes include overcrowding trays, skipping drying steps, or using improper packaging. Overcrowding prevents steam penetration, leaving areas unsterilized. Skipping drying can cause rust and corrosion. Using incorrect wraps may trap moisture. These errors affect both infection control and surgical saw maintenance. Facilities should train staff to recognize these risks. Preventing mistakes reduces repairs and ensures tools remain safe for repeated use.

Note: If corrosion appears repeatedly, it may signal cycle or drying issues rather than tool defects.

Blades require careful handling because they determine cutting precision. Staff should inspect blades after each use for dullness or damage. Cleaning must remove residue without bending edges. Proper blade care reduces friction and improves surgical efficiency. Hospitals often track blade usage cycles. Maintaining sagittal saw blades is essential for both patient safety and tool performance. A dull blade increases procedure time and stress on the motor.

Replacing blades should follow manufacturer guidelines and hospital policies. Signs of wear include reduced cutting speed, visible chips, or unusual vibration. Staff should never attempt to sharpen disposable blades. Replacement ensures consistent performance and reduces risk of intraoperative failure. Proper disposal is also important for staff safety. Routine replacement is a key part of preventive maintenance for orthopedic power tools.

Blade care includes safe storage, avoiding contact with hard surfaces, and using protective cases. Blades should remain dry to prevent corrosion. Handling should minimize risk of injury. Hospitals that prioritize saw blade care often see fewer complications and smoother workflows. Precision cutting supports better surgical outcomes, so blade maintenance is not a minor detail but a core safety practice.

Routine inspections identify issues early. Staff should check for loose parts, unusual noise, or worn attachments. Pre-use checks prevent failures during surgery, while post-use checks support proper cleaning. Inspection routines are often part of a sagittal saw preventive maintenance checklist. These practices reduce downtime and improve reliability. Consistent inspection is one of the simplest ways to protect both patients and equipment.

Some sagittal saw components require lubrication with approved medical-grade products. Lubrication reduces friction and wear. However, excessive lubrication can interfere with sterilization. Staff must follow manufacturer recommendations carefully. Proper lubrication extends motor life and improves smooth operation. Component care also includes checking seals and moving joints. Balanced lubrication supports both performance and sterilization success.

Hospitals benefit from structured checklists that include cleaning, inspection, blade replacement, and servicing schedules. Checklists reduce human error and support accountability. They also help new staff learn proper routines. Preventive maintenance planning improves budgeting and reduces unexpected repairs. A well-designed checklist ensures sagittal saws remain reliable over repeated cycles.

Maintenance Task | Frequency | Benefit |

Visual inspection | Every use | Detects damage early |

Blade replacement | As needed | Maintains cutting precision |

Lubrication check | Weekly/monthly | Reduces wear and friction |

Professional servicing | Annually | Extends tool lifespan |

Drying is essential before storage because moisture causes corrosion. Packaging should maintain sterility until use. Hospitals often use sterilization wraps or rigid containers. Proper drying reduces contamination risk and protects mechanical components. Packaging also supports safe transport. These steps ensure that sterilizing sagittal saw equipment delivers lasting results beyond the autoclave cycle.

Sterile storage areas must remain clean, dry, and organized. Sagittal saw components should be stored in dedicated containers. Poor storage can undo sterilization efforts through exposure to dust or moisture. Facilities should monitor storage conditions regularly. Safe storage protects patients and reduces waste from reprocessing.

Transport must maintain sterility and prevent physical damage. Staff should use covered carts and avoid overcrowding. Dropping trays can compromise packaging and require re-sterilization. Proper transport supports efficient workflows and reduces delays. Clear rules improve compliance and ensure tools arrive ready for surgery.

Storage Factor | Best Practice | Risk if Ignored |

Moisture control | Keep tools fully dry | Corrosion and rust |

Packaging integrity | Use approved wraps | Loss of sterility |

Organized shelving | Separate sterile items | Cross-contamination |

Unusual noise may indicate worn bearings or internal debris. Reduced cutting power may signal motor issues or dull blades. Staff should remove the tool from service if performance changes. Early detection prevents failures during surgery. Troubleshooting supports both safety and cost control. Hospitals should document recurring issues for professional evaluation.

Corrosion often results from moisture retention or improper detergents. Mechanical wear increases if lubrication is skipped. Preventive practices reduce these risks. Staff should ensure complete drying and use only approved cleaning agents. Regular servicing also helps prevent wear. Protecting against corrosion extends tool life and maintains reliability.

Some issues cannot be solved in-house. Persistent vibration, motor failure, or seal damage require professional repair. Hospitals should partner with certified service providers. Professional servicing ensures compliance and restores performance. Ignoring serious issues increases risk and long-term costs.

Tip: Schedule servicing before problems become urgent to avoid operating room disruptions.

Training ensures staff understand correct cleaning and sterilization steps. Compliance protocols reduce variation between shifts. Hospitals often require regular competency assessments. Well-trained teams improve safety and efficiency. Training also supports consistent use of sagittal saw sterilization instructions. Strong protocols reduce infection risks and equipment damage.

Documentation provides traceability for audits and quality control. Hospitals track sterilization loads, cycle parameters, and maintenance actions. Records help identify patterns, such as repeated corrosion. Documentation also supports accountability. Good recordkeeping improves compliance and reduces liability. It is a critical part of professional surgical instrument management.

Orthopedic power tools require specialized workflows due to complexity. Facilities should allocate dedicated trays, trained staff, and validated cleaning methods. Integration improves efficiency and reduces errors. Clear workflows ensure sagittal saws move smoothly from surgery to sterile processing and back. Proper integration supports both safety and cost-effective equipment use. Industry-leading manufacturers such as Chongqing Xishan Science & Technology emphasize precision engineering and compatibility across powered surgical instrument systems, which helps hospitals streamline processing and reduce long-term maintenance burden.

Workflow Step | Key Action | Outcome |

Post-surgery handling | Immediate pre-cleaning | Reduces residue buildup |

Sterile processing | Disassembly and cleaning | Ensures full sterilization |

Autoclave cycle | Validated parameters | Kills pathogens effectively |

Storage and transport | Dry, protected packaging | Maintains sterility |

Sterilizing and maintaining a sagittal saw is essential for safe surgery and reliable orthopedic power tools. A step-by-step sagittal saw sterilization process reduces infection risks and supports operating room safety. Proper cleaning, disassembly, and autoclave cycles prevent corrosion and mechanical failure. Blade care and preventive maintenance extend tool life and cutting performance. High-quality systems from Xishan provide durable design and value for hospitals through consistent sterilization support.

A: Sagittal saw sterilization prevents cross-contamination and supports operating room safety.

A: Follow a step by step sagittal saw sterilization process with cleaning, disassembly, and autoclave sterilization.

A: Proper surgical saw maintenance and blade care reduce corrosion and extend tool lifespan.

A: Skipping drying or overcrowding trays can damage orthopedic power tools and reduce sterilization results.

+86-23-65764808

+86-23-65764808