Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

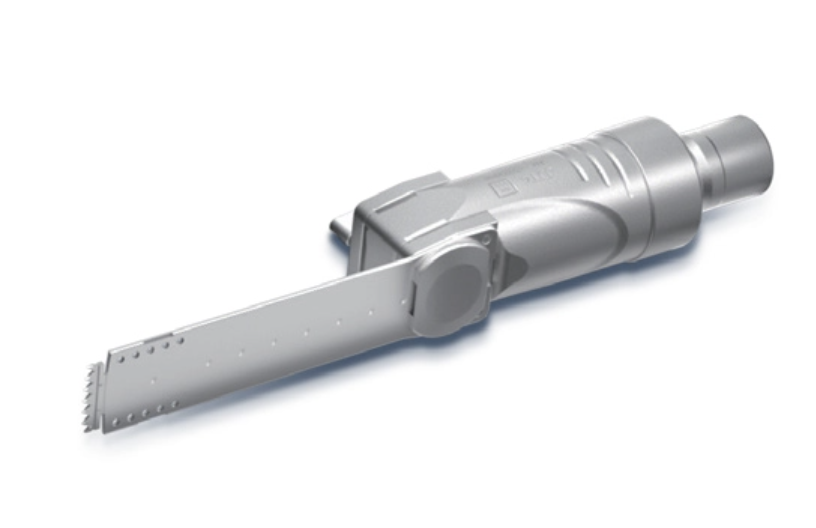

Choosing between an electric vs battery powered sagittal saw can shape operating room safety and efficiency. This decision affects cutting power, mobility, comfort, and long-term sagittal saw cost. In this guide, you will learn a clear surgical saw comparison for selecting the best sagittal saw for operating room use. High-quality systems from Xishan support reliable performance, so you can learn more about our products and options.

The power source of a sagittal saw directly influences how well it performs during surgery. Electric vs battery powered sagittal saw systems differ in how they deliver torque, cutting speed, and stability under load. In large bone trauma surgery, surgeons often require consistent cutting force without interruption. A corded electric sagittal saw may offer steady output, which helps maintain precision. Battery systems, however, provide portability and reduce clutter. The power source also affects reliability in long cases, where interruptions can increase anesthesia time. Understanding these differences is essential when evaluating orthopedic power tools for operating room use.

Operating room sagittal saw power tool selection should consider workflow, ergonomics, and risk control. Surgeons need tools that feel balanced and reduce fatigue during long procedures. Sterile processing teams need devices that can be cleaned and sterilized efficiently. Biomedical departments look at maintenance schedules, service life, and repair costs. Battery powered sagittal saw advantages and disadvantages often include mobility versus the need for charging and spare batteries. Electric systems may require cable management but reduce downtime related to battery failure. These factors combine into a decision that must fit the hospital’s daily surgical demands.

Not every procedure requires the same sagittal saw performance profile. In microsurgery or delicate cranial work, weight and precision matter more than raw power. In contrast, joint replacement or trauma surgery often requires high cutting strength. Cordless sagittal saw for surgical procedures can be valuable in minimally invasive workflows where freedom of movement is critical. Electric sagittal saw performance comparison becomes especially relevant in high-demand orthopedic environments. Matching the power tool to procedure type ensures better surgeon control, fewer complications, and improved operating room efficiency.

Corded electric sagittal saw systems are known for delivering continuous power throughout a procedure. Because they are connected to mains electricity, they avoid the risk of battery depletion during critical moments. This makes them appealing for long orthopedic surgeries where cutting must remain consistent. Electric sagittal saw advantages often include lower upfront cost compared to advanced cordless systems and reduced dependency on battery replacement cycles. However, cables can restrict movement and create hazards in crowded operating rooms. For hospitals prioritizing stable performance, corded systems remain a strong choice.

Cordless surgical saw designs have become increasingly popular because they remove cables from the sterile field. A battery powered sagittal saw allows surgeons to reposition freely, which is especially helpful in complex orthopedic angles or minimally invasive procedures. Mobility can improve workflow and reduce setup time. However, cordless systems may weigh more due to lithium batteries, and teams must manage charging routines. Battery powered sagittal saw advantages and disadvantages often center on convenience versus power autonomy. In modern operating rooms, cordless mobility is often seen as a major operational benefit.

Reliability is critical when choosing between electric vs battery powered sagittal saw options. Corded systems provide uninterrupted power, which reduces anxiety about tool failure mid-procedure. Battery powered tools rely on charge level, battery health, and availability of spares. In long surgeries, autonomy becomes a key concern. Hospitals must ensure batteries are fully charged and maintained. Consistency also affects cutting precision and surgeon confidence. Reliable orthopedic power tools reduce downtime, improve surgical outcomes, and support smoother operating room workflows.

Electric sagittal saw advantages are most visible in demanding orthopedic and trauma cases. These procedures often involve dense cortical bone that requires steady torque and cutting speed. A corded electric system delivers consistent energy without drop-off. This reduces the chance of uneven cuts and improves implant placement accuracy. Surgeons also benefit from predictable performance, which supports faster procedure times. Electric sagittal saw performance comparison often highlights stability under heavy load as a major strength. For hospitals handling frequent trauma workloads, corded systems may provide dependable cutting performance.

Battery powered sagittal saw advantages include portability, reduced cable hazards, and easier movement around the surgical field. These systems can improve sterility by eliminating cords that may touch non-sterile surfaces. However, disadvantages include battery weight, limited runtime, and the need for spare batteries. Performance may decline if battery charge is low. Hospitals must invest in battery management programs to avoid interruptions. In surgical saw comparison discussions, cordless tools are often favored for flexibility, but they require more operational planning.

Surgeon comfort depends on vibration control, noise levels, and tool balance. Excess vibration can reduce precision and increase fatigue. Noise may raise stress in the operating room. Modern orthopedic power tools aim to reduce vibration through improved transmission design. Cordless systems sometimes weigh more, which can affect handling. Electric sagittal saw performance comparison should include these ergonomic factors, not just cutting strength. Tools that provide smooth operation help surgeons maintain control and reduce risks of accidental tissue damage.

Cable management is a major workflow issue in operating rooms. Corded electric sagittal saw systems require careful positioning to avoid contamination and tripping hazards. Cables can also limit surgeon movement during complex procedures. Cordless surgical saw designs reduce these risks by removing external connections. This supports cleaner workflow and easier instrument handling. However, cordless tools require battery charging logistics. Operating room teams must balance sterility benefits against battery maintenance demands when selecting the best sagittal saw for operating room use.

Ergonomics matter because surgeons may hold sagittal saws for extended periods. A lighter, well-balanced tool reduces fatigue and improves precision. Battery powered sagittal saw systems may be heavier due to battery packs. Corded systems may feel lighter but can pull against cables. Comfort impacts not only surgeon experience but also surgical outcomes. Operating room sagittal saw power tool selection should consider how weight and balance align with procedure length and surgeon preference.

Freedom of movement is one of the strongest arguments for cordless sagittal saw for surgical procedures. Surgeons can reposition quickly without worrying about cable drag or sterility compromise. This is valuable in minimally invasive orthopedic cases where access angles are limited. Mobility can shorten procedure time and improve workflow. However, hospitals must ensure battery readiness. Cordless flexibility delivers clear value when supported by strong operational protocols.

Cost is a major factor in electric vs cordless surgical saw cost decisions. Corded electric sagittal saw systems often have lower initial purchase prices. Battery powered systems may require higher investment due to advanced battery technology and charging infrastructure. Hospitals must consider budget constraints and expected surgical volume. Upfront cost should also be weighed against performance needs. A cheaper system may not meet high-demand requirements, while a premium cordless tool may offer workflow advantages.

Battery replacement is one of the key long-term costs for cordless systems. Lithium batteries degrade over time and must be replaced regularly. This adds ongoing expense. Corded systems avoid battery replacement but may require cable repairs or motor servicing. Surgical saw maintenance programs must account for these differences. Hospitals evaluating sagittal saw cost should consider total cost of ownership, not just purchase price.

Hospital budgeting requires a full lifecycle view of equipment costs. This includes purchase, maintenance, sterilization compatibility, downtime risk, and replacement parts. Electric vs battery powered sagittal saw comparisons should include service contracts and expected lifespan. Tools that reduce downtime may offer better long-term value. Budget planning should align with procedure demand and operating room expansion goals.

Cost Factor | Electric Sagittal Saw | Battery Powered Sagittal Saw |

Upfront price | Often lower | Often higher |

Ongoing costs | Cable/service maintenance | Battery replacement cycles |

Downtime risk | Low power interruption | Depends on battery readiness |

Note: Always calculate total cost over several years, not just the purchase price.

Electric sagittal saw systems require careful cleaning because of cable connections and motor housing. Sterile processing teams must follow manufacturer guidelines to prevent moisture damage. Corded designs may have more external components to manage. Proper disassembly and inspection are essential. Maintenance routines reduce corrosion and mechanical wear. Hospitals must ensure cleaning workflows align with operating room schedules. Reliable sterilization supports both patient safety and equipment longevity.

Battery powered sagittal saw systems introduce unique sterilization concerns. Batteries cannot typically undergo high-temperature autoclave cycles. Staff must remove and store them separately. This adds steps to sterile processing workflows. Hospitals must train teams to avoid damaging battery compartments. Autoclave compatibility is critical for attachments and handpieces. Some surgical power tool attachments, including sealed high-temperature designs like Xishan saw attachment solutions, are engineered to withstand repeated steam sterilization cycles. Battery powered sagittal saw advantages and disadvantages include added complexity in sterilization routines.

Preventive maintenance extends the life of orthopedic power tools. Regular inspections, lubrication checks, and servicing reduce breakdowns. Both corded and cordless systems benefit from structured checklists. Preventive care also improves reliability during surgery. Hospitals that invest in maintenance programs often reduce repair costs and improve patient outcomes.

Maintenance Area | Key Action | Result |

Inspection | Check wear before use | Prevents failures |

Sterilization prep | Proper disassembly | Ensures safety |

Battery care | Charge and store correctly | Extends autonomy |

Trauma and large bone surgeries often demand high cutting strength. Electric sagittal saw systems provide consistent power for these high-load applications. Surgeons benefit from uninterrupted performance. In emergency trauma settings, reliability matters more than portability. Corded systems may be preferred where power stability is critical. Hospitals specializing in trauma care often prioritize electric sagittal saw advantages.

In microsurgery, weight and fine control are more important than maximum power. Battery powered sagittal saw systems may be less suitable if weight increases fatigue. Surgeons may prefer lighter tools that provide delicate precision. Procedure type should guide selection. Operating room sagittal saw power tool selection must align with the surgical specialty’s unique needs.

Minimally invasive procedures benefit from cordless mobility. Cordless surgical saw designs reduce clutter and improve surgeon access. Battery powered sagittal saw advantages include flexibility and sterility support. Hospitals adopting minimally invasive orthopedic programs often favor cordless systems for workflow efficiency. Portability can also support outpatient surgical centers.

Battery autonomy is a common concern in cordless systems. If batteries are not fully charged, power loss can occur during surgery. Hospitals must maintain spare batteries and charging stations. Battery health monitoring is essential. Surgical saw comparison discussions should address autonomy management as a key operational factor.

Corded systems introduce cable hazards, including tripping risks and contamination potential. Proper cable routing reduces these risks. Operating room staff must remain aware of cord placement during procedures. Cable issues can disrupt workflow. Hospitals should include cable management in safety training.

Downtime is costly for surgical departments. Tools requiring frequent repairs reduce operating room efficiency. Reliability depends on maintenance routines and supplier support. Hospitals should evaluate service availability when selecting orthopedic power tools. A reliable sagittal saw system improves scheduling stability and patient care.

Tip: Ask suppliers about service turnaround time and spare part availability before purchasing.

Hospitals should create structured checklists when choosing sagittal saw systems. These include procedure demand, surgeon ergonomics, sterilization compatibility, and cost planning. A checklist approach reduces bias and ensures all stakeholders contribute. Operating room sagittal saw power tool selection should reflect real workflow needs.

Key questions include battery lifespan, motor durability, sterilization requirements, and service support. Hospitals should request performance data and clinical references. Supplier transparency improves purchasing confidence. Comparing answers helps clarify which sagittal saw is better for orthopedic surgery in specific environments.

The best sagittal saw for operating room use depends on balancing multiple priorities. Electric systems offer stable power and lower autonomy concerns. Battery powered systems offer mobility and reduced cable hazards. Hospitals must align selection with procedure mix, staff training, and long-term budget planning. Balanced decisions lead to better surgical outcomes and smoother operations.

Decision Priority | Best Option |

Continuous cutting power | Electric sagittal saw |

Mobility and flexibility | Battery powered sagittal saw |

Lower upfront investment | Corded electric system |

Minimizing cable clutter | Cordless surgical saw |

Choosing between an electric vs battery powered sagittal saw can shape operating room safety and efficiency. This decision affects cutting power, mobility, comfort, and long-term sagittal saw cost. In this guide, you will learn a clear surgical saw comparison for selecting the best sagittal saw for operating room use. High-quality systems from Xishan support reliable performance, so you can learn more about our products and options.

A: An electric vs battery powered sagittal saw differs in power source, mobility, and workflow needs.

A: The best sagittal saw for operating room use depends on cutting demand, comfort, and cordless flexibility.

A: Battery powered sagittal saw advantages and disadvantages include mobility benefits but charging and weight concerns.

A: Electric vs cordless surgical saw cost varies by upfront price, battery replacement, and long-term maintenance.

+86-23-65764808

+86-23-65764808